10 Cost Effective Packaging Options that are Sure to Impress Your Audience

Both small and big businesses share a common goal—to differentiate their product from others by marketing their product’s benefits, competitive pricing and attractive packaging. Customers usually are not be able to discern a product’s quality and features over others if they do not purchase it. Businesses need to present eye-catching, and value-added packaging for their products to increase the likelihood that a customer chooses their product rather than the competition.

Businesses have to customize their packaging, keeping their target market’s preferences in mind. However, packaging plays a far greater role in the success of a business. Inherent branding and packaging design improves customer retention and their ability to recall the name of a brand just by looking at the colors and design language of their style of their line of boxes.

To stand out, businesses need to design a unique look, specific to their brand and product line, adding their text, logo, company/product colors, product details, and product/company name. They should focus their packaging efforts on accomplishing the following three goals:

- Reflect a business’s positioning

- Reflect values of target market

- Communicate visual identity

Generally, to fulfill all three goals, it is assumed that companies need to invest a large amount of capital in their packaging design, while paying hefty prices for manufacturing custom boxes. This makes it more difficult to price their product competitively in the global economy. This creates a significant problem for small businesses that do not have the funding to invest in expensive packaging options. Luckily, plenty of affordable and attention-grabbing packaging options exist today and as the packaging industry grows more and more competitive, box manufacturers and suppliers are forced to keep up with new technology and offer competitive pricing. A business in search for a high quality and attractive packaging option should consider some of these attractive packaging options:

1. Foil Stamping

When people think of foil stamping, they associate it with seasonal or promotional packaging—shiny graphics and designs. This viewpoint has prevented most businesses from using foil stamping, using it only during the holidays. Another reason that has deterred them from utilizing foil stamping is the negative impression it creates for a brand.

Therefore, Perception Research Services decided to conduct a research on the effectiveness of foil stamping, interviewing more than 14,000 people at different malls. The study concluded that foil stamping had a positive impact on product expectations, aesthetic appeal, and brand imagery. The study revealed further that it increased buying interest more than 70% of the time.

2. Embossing

Embossing designs a pattern on metal, leather, fabric, wood, or paper. The designers accentuate the pattern, lettering, or graphic by depressing the backdrop. Embossing draws customers’ eyes to the accentuated brand or logo.

Embossing increases the attractiveness of packaging and provides it with a distinguished appearance. Different embossing techniques allow the image to be either raised or in relief. Embossing creates a raised surface whereas debossing creates a depressed surface.

Often, businesses use the two techniques together to design packaging for their product. Embossing focuses buyers’ attention to the logo in a sophisticated manner and adds depth to a two-dimensional box.

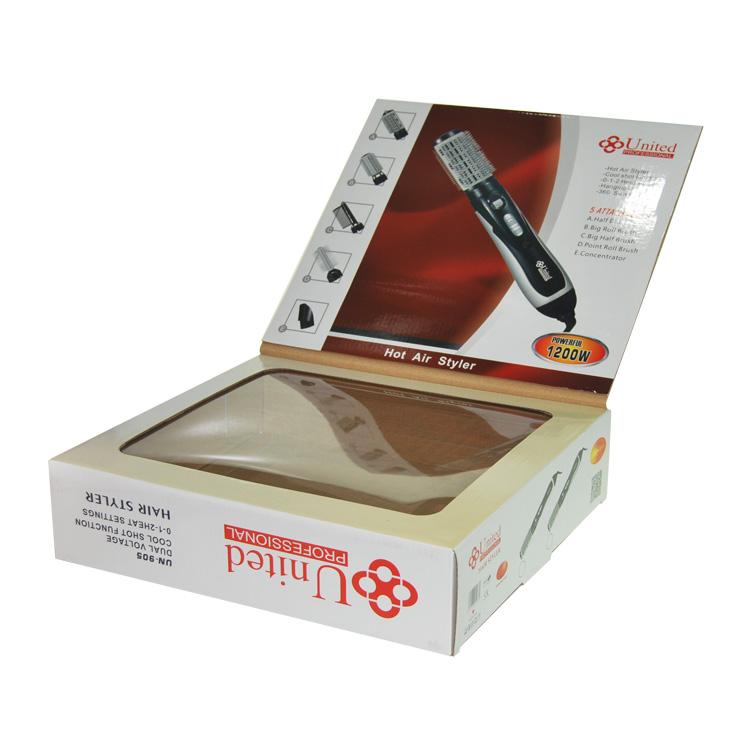

3. Rigid Boxes

Rigid boxes offer the product a protective covering. If the item is a perfume, cologne, crystal, or an electronic device, customers will most likely find it encased in a rigid box. The rigid box opens in a variety of different ways and manufacturers can manipulate the inside of the box, molding it to the product’s shape using a technique called expanded polystyrene or vacuum formings.

Sometimes, businesses do not opt to conceal the product from view entirely, adding window patching and transparent lids to the design. The design process consists of using a variety of different materials to construct it, from recycled board to coverings fabrics, papers, etc.

The rigid box receives its unique appearance from the covering materials, which include papers, foils, fabric linings, and leather. To increase the attractiveness of the rigid box further, manufacturers decorate it with handles, bows, ribbons, etc.

4. Window Films

Businesses opt for window film packaging boxes for a many different reasons. One of the most common reasons is to display the product through a window while keeping the box sealed. By providing customers with a glimpse of the product, it works to retain their attention rather than walking pass it at the store.

For instance, rigid boxes can include window films. To create window films, manufacturers utilize the die-cutting process. They cut the window to fit the size requirement of the box. Next, they glue a section of overlapping plastic film to the back of the window using a window gluing tool.

They apply the glue around the opening of the window on the backside of the box. They cut a section of plastic film before positioning it over the window, and then carefully set it on the glue.

5. Creative Box Styles

Businesses aim to make their packaging style different from their competitors. Businesses using the same creative box style as their competitors set themselves apart by designing their packaging box using different colors.

They can create packaging for their box using the following creative box styles:

With many different creative folding carton box styles available, businesses do not need to mirror their competitor’s design.

- Half Circular Interlocking Top Flaps Box

- Hexagon Box

- Auto-Lock Cap Box

- Cube Shaped Carrier

- Flower Shaped Top Closure Box

- Square Box With Ladder Top

- Hinged Lid Cosmetic Rigid Boxes

- Book Style Rigid Boxes

6. Recycled Content

Businesses can often lower their packaging costs if they choose to use recycled content such as paper, metal, glass, plastics, and cardboard. However, they are not only lowering their costs, but are also benefitting the environment.

It sends potential customers a positive message about the business, informing them the business meets all the regulatory and legal requirements and most importantly, cares for the environment. In short, using packaging boxes made using recycled content streamlines the production of the business by lowering their overall manufacturing costs.

7. Metallic Paper Stock

Metallic paper stock enhances the appearance of the printed box. This type of packaging option is popular with businesses selling beauty, wine, and gift products. Metallic paper stock creates impressive graphics and designs on the box’s outer surface.

Metallic, gloss/matte, and holographic are three types of stock paper. Manufacturers transfer the design from the foil to the box using the foil stamping technique. The foil stamping technique involves the die coming in contact with the paper, which then transfers a thin layer of the metallic stock paper onto the box.

8. Spot UV

Spot UV is just one type of varnish used to coat a corrugated print box, a rigid box, cosmetic box, paper bag, and more. The advantage of using glossy, matte, satin or silk, and UV varnishing is that it dries up the printing ink faster, it is rub resistant, and provides the surface of the box with a smooth and even texture.

Out of the four types of varnishing available, businesses should opt for UV varnishing. UV varnishing provides the packaging box with a thicker and a more impressive appearance. The printed color on the box appears richer and vivid as well. Businesses can choose from two types of UV vanishings, all-over and spot UV varnishing.

In the all-over UV varnishing, manufacturers apply ink on every inch of the printing surface. This option provides the box with richer glossy appearance. In the spot UV varnishing, the manufacturer only applies the ink to a specific area.

This highlights the text, graphics, and logo on the box, emphasizing their appearance. Businesses use spot UV varnishing on luxury boxes, paper bags, cosmetic boxes, gift boxes, retail boxes, and jewelry boxes.

9. Print Quality (offset printing)

Offset printing or litho offset printing enhances the appearance of the graphics by making the colors more vivid and images sharper. The offset printing process involves transferring the image from the printing plate to a rubber blanket cylinder, and then to the paper.

Offset printing increases the lifespan of the text and graphics, preventing them from fading. Businesses that want to create an eye-catching display should try offset printing, as it improves quality of the text, images, logo, and graphics on the box.

10. Lamination (Gloss and Matte)

In the lamination process, the manufacturers take a think transparent plastic film and apply it the surface of the box. This provides additional support to the packaging and gives the box waterproof qualities. Additionally, lamination helps preserve the printing on the box, making it last for several years.

Businesses can choose from either a gloss or matte lamination, but both create a striking effect. The gloss lamination method provides the box with a shiny appearance whereas the matte lamination method provides the box with a satin-like finish. Businesses that are looking to cut costs should opt for gloss lamination, as matte is a little bit more expensive.

Small businesses owners can use these ten cost-effective packaging options to put their product in the spotlight. Businesses can use a combination of these packaging options to design an ideal packaging box to keep their product.

By using multiple options to create a packaging box, businesses will have an increased chance on ensuring that their product receives attention from onlookers in grocery stores and retail stores. They should also scout out the competition to see what type of packaging options their competitors have chosen.

This guest post was written by Benjamin Liu.

Benjamin Liu is a Product Specialist and Editor at PakFactory, a leading packaging company that provides premium custom boxes and packaging solutions. Benjamin strongly believes that successful packaging leads to a successful product.